In total, Egypt has currently 24 cement plants. The major players are Cemex, Lafarge, Italcementi and Titan Cement. Of these 24 cement plants, 16 are already equipped with SICK gas analyzers, dust and or flow monitors from HAK. The market for emission and process analyzers - especially for CEMS - is still growing in Egypt. The reason for this is that the environmental law amendment of 2011 forces all industries - especially cement plants - to install CEMS solutions for gases and the calculation of dust loads, as well as for gas flow measurement.

Market potential for HAK and SICK

The local market potential is relatively high for HAK and SICK. This is based on two facts: SICK’s variety of technologies and applications for process and emission measurement, as well as the strong local support and service provided by HAK, SICK’s Egyptian partner, during the last several years.

The story about HAK, SICK and Cemex’s Assiut cement plant

For the Assiut cement plant, the story started in 1999. One year after signing a partnership agreement between HAK and SICK, HAK received its first order from the Assiut cement plant to supply nine dust monitors. This was followed in 2006, by another six new dust monitors, replacing those of BHA, and upgrading of the existing seven dust monitors. Then in 2008, HAK won the first installation of three MCS100E HW units using hot-wet technology for raw mill stacks.

In 2013, the success story continued. HAK won a new project for the installation of two gas analyzer systems for two kiln inlet applications at the Assiut cement plant.

Project details and success factors

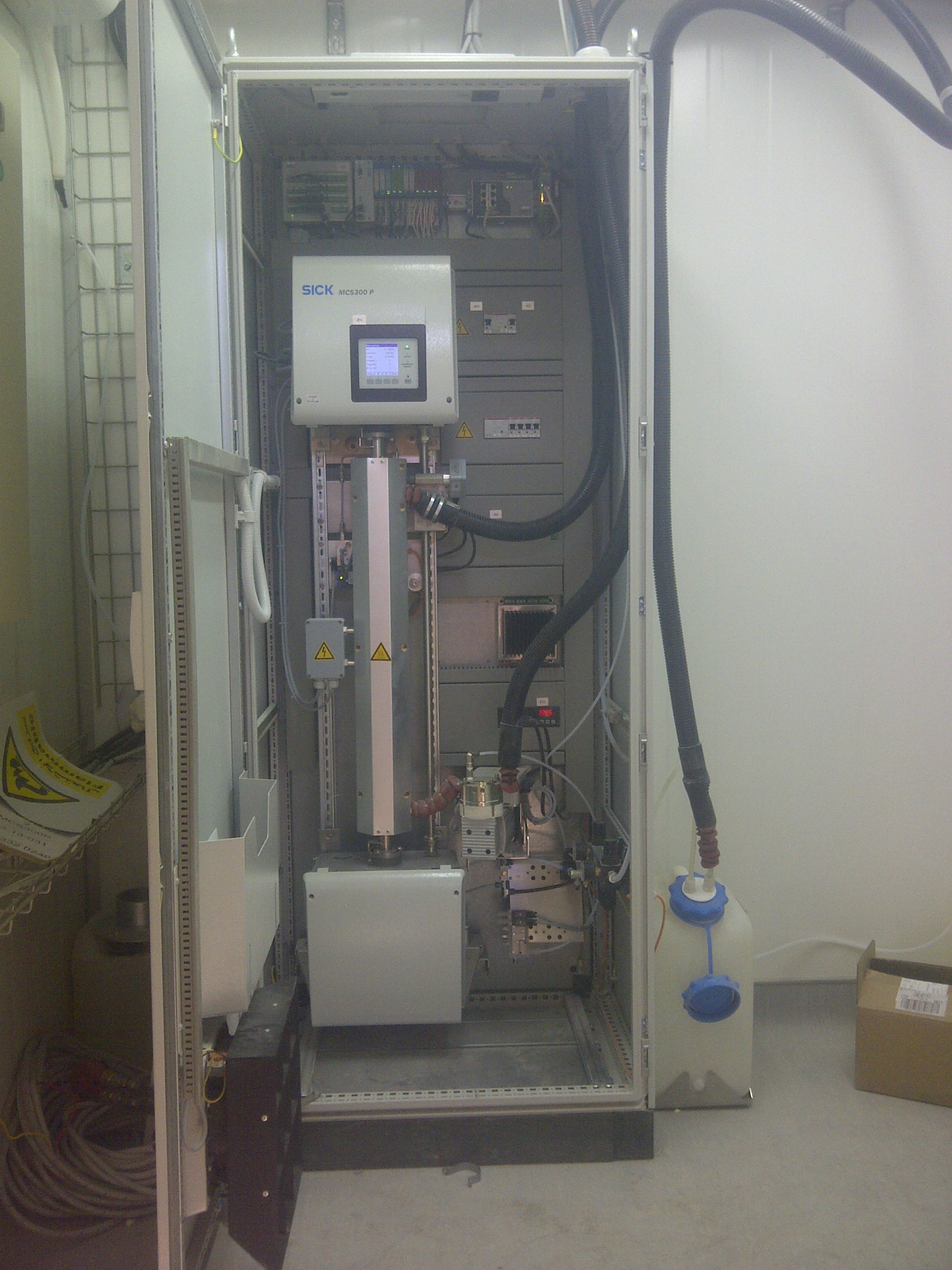

This recent kiln project is the conclusion of a strong and successful collaboration between HAK and SICK. SICK’s best solution was preferred by CEMEX due to the strong after-sales services and the proven local support by HAK. The professional installation and strong support of the existing three CEMS MCS100 E HW solutions and thirteen dust monitors was one of the key factors in the customer evaluation. SICK’s best solution of MCS300P and SCP3000, using hot wet technology was preferred over FLsmidth and ABB.

Within CEMEX worldwide, this project was the first installation for kiln inlet measurement realized with the MCS300P and

SCP3000 devices. For CEMEX’s first kiln inlet project in Odessa, Texas, an MCS100E HW unit together with a SCP3000 were installed.